SPECTRA™ Nano-Particle Lipid Esters

Palm Oil Mills are losing more CPO than recorded. This can be proven with Acetone tests compared to the standard Hexane tests. This equates to millions in 'lost oil'. Billions lost to the nation. SPECTRA™ 'frees' the 'lost oil', lowers its FFA, Phosporus & Chloride levels and produces high quality CPO for the Palm Oil Mill.

Mass Balance : The Inaccurate Picture

Hexane, the industry standard in measuring oil losses in the underflows, is unable to measure emulsified oils. Acetone's chemistry frees the emulsified oils, resulting in a higher (and more accurate) reading of actual oil losses in the Palm Oil Mill. Unfortunately, due to cost and safety resons of, the industry adopted Hexane. Subsequently miscalculating the true losses to the industry.

Enter SPECTRA™

SPECTRA™ is a revolutionary class of Food-Grade Surfactants called Nano-Particle Lipid Esters (NPLE). It has the unique ability of recovering the unrecoverable oil from emulsions i.e. mostly from under-ripe fruits and the loose fruits getting emulsified during the sterilisation process. This allows millers to recover the ‘lost’ CPO at the front end of the milling process. Palm Oil Mills using SPECTRA™ NPLE are recording significant increases in OER immediately upon dosing.

SPECTRA™ is added to the mill system at the Crude-Oil-Tank (COT). It frees the oil cells that are bound within fibres and in the third layer in colloidal form. These were previously lost in the process and removed as sludge and waste. This is realising hundreds of millions of dollars in increased revenue for the industry. There are also important breakthroughs in addressing the issues with the health hazardous GE and 3-MCPD.

“SPECTRA™ is produced from Fatty Acids of Crude Palm Oil, Crude Palm Kernel Oil and Refined, Bleached & Deodorised (RBD) Palm Olein. It has no effect on the characteristics of the CPO.”

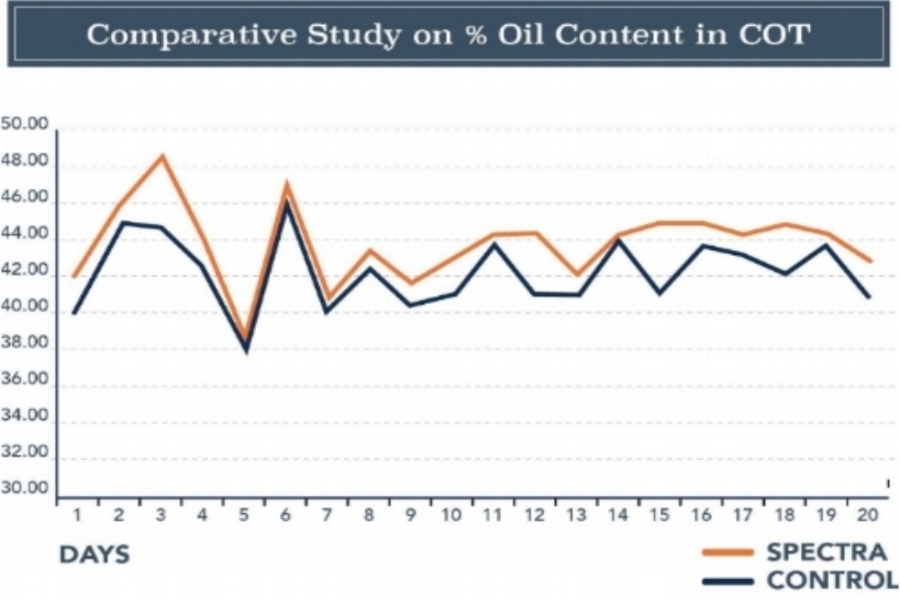

COT Oil Content Pre and Post SPECTRA™ Dosage

Petri dish on the right is dosed with SPECTRA™ showing more oil from de-emulsification and cell-wall lysing.

SPECTRA™ increases percentage of oil recovered from Steriliser Condensate and EFB Liquor that could be recycled as Diluent in the Milling process.

By De-Emulsification, Palm Oil Mills using SPECTRA™ NPLE are recording about 1% OER rise.

By using SPECTRA™, the EFB Liquor and Steriliser Condensate Oils that are recovered have superior Oil qualities i.e. FFA, DOBI, GE, Phosphorus, Total Chloride (organic and inorganic), Anisidine (AV) and Peroxide Values (PV). These Oils can be recycled as Diluent in the Milling process, while maintaining CPO quality.

*Averages from 20 mills over a 12 month average

SPECTRA™ NPLE is being commercially used in Palm Oil Mills, Crop Protection, Livestock/Poultry, Aquaculture, Industrial Waste Water Treatment, Oil & Gas and Pharmaceutical sectors both locally and internationally.

The ingredients are defined as non-hazardous under OSHA Standards 29 CFR1910 1200. SPECTRA™ carries an international Patent.

The manufacturing process has ISO and HACCP certifications.

SPECTRA™ also complies to the European Food Safety Standards.

Schedule A Technical Presentation Today

Write to us at spectra@bpp.ag